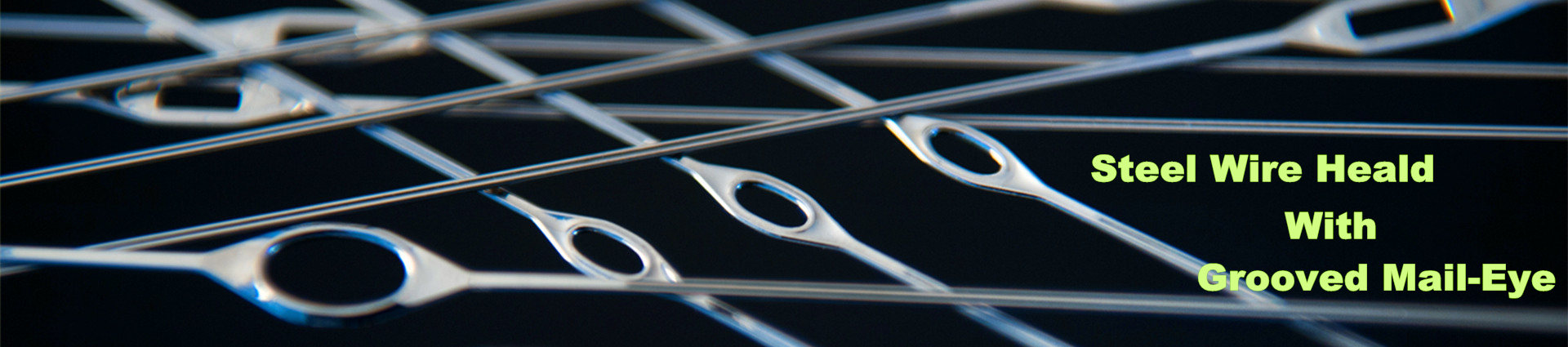

- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

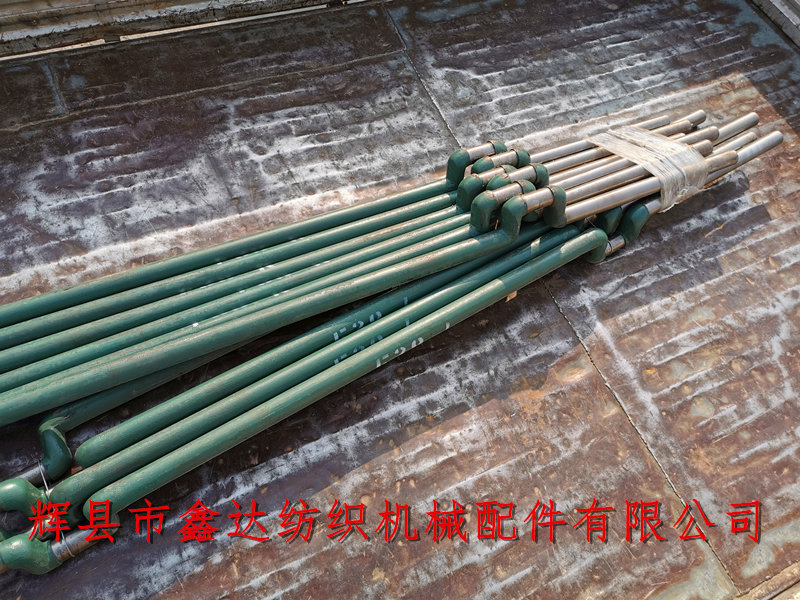

Our company provides f38 bending shaft accessories for metric loom. The diameter of metric crank shaft (bending shaft) F38 is 38mm, which is divided into R right hand and L left hand. The material is 45 # steel. Its total length is 2098mm, and the distance between two bending handles is 1391mm. The 44 inch metric loom bending shaft is fixed on the spherical wall panel and connected with spherical bearing D00-1 (the pin loom is connected with D1xD2 copper sleeve).

In the figure above, the width of keyway of metric F38 bending shaft is 12mm. The triangular belt pulley F00-4 is installed on the shaft head on one side, D7 (36 teeth) crank shaft gear is installed on the outside of bending, and the bearing bush k77x78 (copper sleeve or nylon sleeve) of handle assembly is installed in the middle of the crank.

On the other side, hand wheel D8 and skew wheel D11 are installed on the 1511 loom. For the processing of shaft products of textile machinery, we support customized crank shafts and bent shafts with various door widths and diameters (38 mm, 40 mm, 42 mm), such as 28 inch, 32 inch, 36 inch and 110 inch loom crank shaft.

Textile crank shaft is the transmission part of loom frame. It continues to provide power to reed foot and reed after weft is woven into cloth surface. 44 loom bending shaft belongs to shuttle textile machinery frame. If you need 1511 textile accessories crank bending shaft processing service, please contact our company for details.

Installation instructions: the vertical distance between metric bending shaft F38 and tread plate shaft F9 is 343 mm (just the length of nylon shuttle, 13.5 inches), and the allowable difference is ± 0.1-0.3 mm. Use 343 mm setting gauge, level ruler and micrometer to check the position of P1 and P2 against the wall panel, and the left and right installation position of bending shaft is appropriate.

Check the bending of crank shaft F38 with dial indicator. When the bending shaft rotates, the warp runout is less than 0.05mm, and the transverse movement is less than 0.4mm. The crank F38 of loom can rotate flexibly. When the bending shaft accessory-1511 crank of 44 inch loom is turned to 45 degrees before and after the upper center, it should fall down freely and swing back twice.