- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

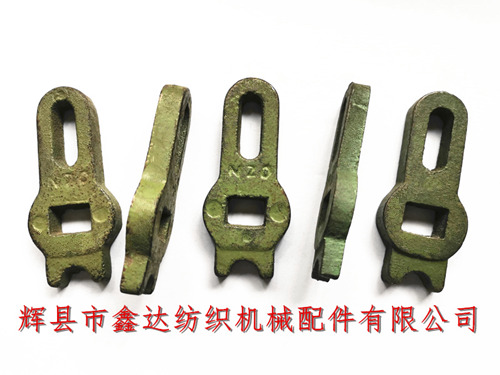

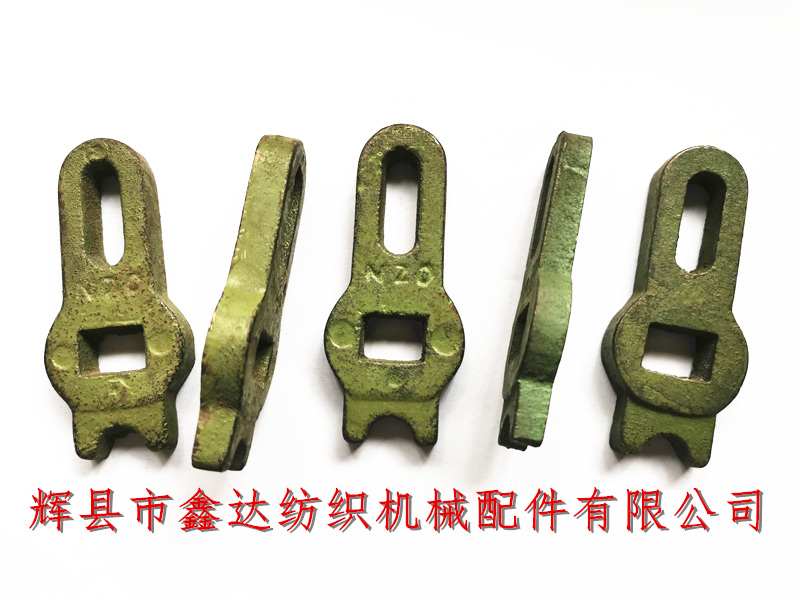

Huixian Xinda Textile Accessories Co., Ltd. provides automatic shuttle change accessories movable shaft holder for N20 loom. The length, thickness and width of the loom holder N20 are 9.2 cm, 9.4 mm and 3.9 cm respectively. The material is gray iron HT15-33. It is connected with the shuttle stock (inner n19 and outer N18, which are divided into left hand and right hand) of automatic shuttle changer loom. The weight of N20 movable axle bracket is 0.125 kg / piece.

Put the shuttle into the shuttle magazine of the loom, hang the wire hammer, bend the shaft in the front dead center, lift the front brake rail, correct the gap between the two and the shuttle magazine is vertical. If it is not vertical, the screw on N21 adjusting hoop on the shuttle magazine shaft can be adjusted. If the front and rear positions are not correct, angle rods N18 and n19 can be used as fulcrum to adjust the supporting foot N20 of shuttle magazine shaft, so as to ensure that the gap between shuttle in shuttle magazine and front brake rail is equal. The vertical adjustment of the hangar should be combined with the front and back.

The shuttle magazine is installed on the inside and outside angle bars (n19, N18) through movable shaft support feet (N20), and the inner angle bar n19 is installed on the upper plane of the shuttle changing side of the breast beam 4306, and the position is as far as possible to the rear and outside of the machine; the outer angle bar N18 is installed on the propeller guide foot 3701, which should be roughly flush with the back and upper edges of the propeller guide foot. When adjusting the front and rear and high and low positions of the shuttle magazine, the N20 loom is fixed to automatically change the shuttle Accessories movable shaft bracket.

Adjustment of the high and low position of the hangar: the height position of the hangar shall be based on the distance between the pallet feet n16 and n17 and the bottom plate (3308) of the shuttle box. During the inspection, lift the front convex edge plate k64, and use the three-purpose setting gauge (6-104) to check. If not, adjust the upper and lower positions of the movable shaft (n41) in the long hole of the movable shaft bracket (N20).

If you want to purchase loom N20, automatic shuttle changing accessories, loom feet and other products, please contact Mr. Yang of our company for consultation. We welcome all textile customers to come. We adhere to the business philosophy of "integrity management, pragmatic and enterprising" to provide textile accessories processing and batch distribution business for the majority of textile enterprises.